I unscrewed the plate and pulled it up to find that this section of the bilge held about three gallons of diesel fuel!! Luckily there were no limber holes in this area, so the fuel was contained and not going into the bilge pumps.

I assumed this happened as a result of my fuel filter changes, but that seemed really careless to miss three gallons because I'm not that careless. So I was puzzled. I pumped it out with my oil change pump, polished the bilge clean and dry, and left the cover off. The next morning I arrive to find about a quarter cup of fuel in the same place. I traced the seep lines, cut back the insulation and aluminum plate covering a small portion of the bottom side of my fuel tank, and found a small pocket in the fiberglass side of the tank that is open on top. It seeps very slowly and has probably been seeping for months. Luckily my procrastination for going to the fuel dock and refilling the tanks played in my favor this time. I tried an epoxy patch, but the 8" head of fuel was too much and pushed thru before it set. I think I will now install a fuel transfer pump and redo the patch. N.B. If your partner says something doesn't smell right, listen and follow those suspicious indicators to their source. PART 2 Fixing the Fuel LeakIn the last issue I described the fuel leak I found in my fuel tank. The transfer pump I had installed worked well to move fuel from one tank to the other, but still left fifteen gallons in the tank! I used my oil change pump to pump out the last of the fuel. I used a West Marine water/fuel funnel to filter the last dregs of the fuel tank to see how much water and sediment were in the bottom of my tank. I was pleasantly surprised to find no water and almost no sediment. I discovered that the fuel leak was from the brass fitting that was installed thru the 1/2" wall of the fiberglass tank, not thru the tank itself. The sealant around the fitting was starting to soften and allowed the seep. This was a flanged brass fitting with a brass nut on the inside of the tank. The fitting was hollow and threaded and allowed the installation of a valve to control fuel flow to the tank site gauge when it was open.

I know I'm just a structural engineer and not a mechanical engineer, but it seems to me the flange should be on the inside of the tank and not the outside. So I removed the fitting and had it machined so I could reverse it and put the flange on the inside of the tank.

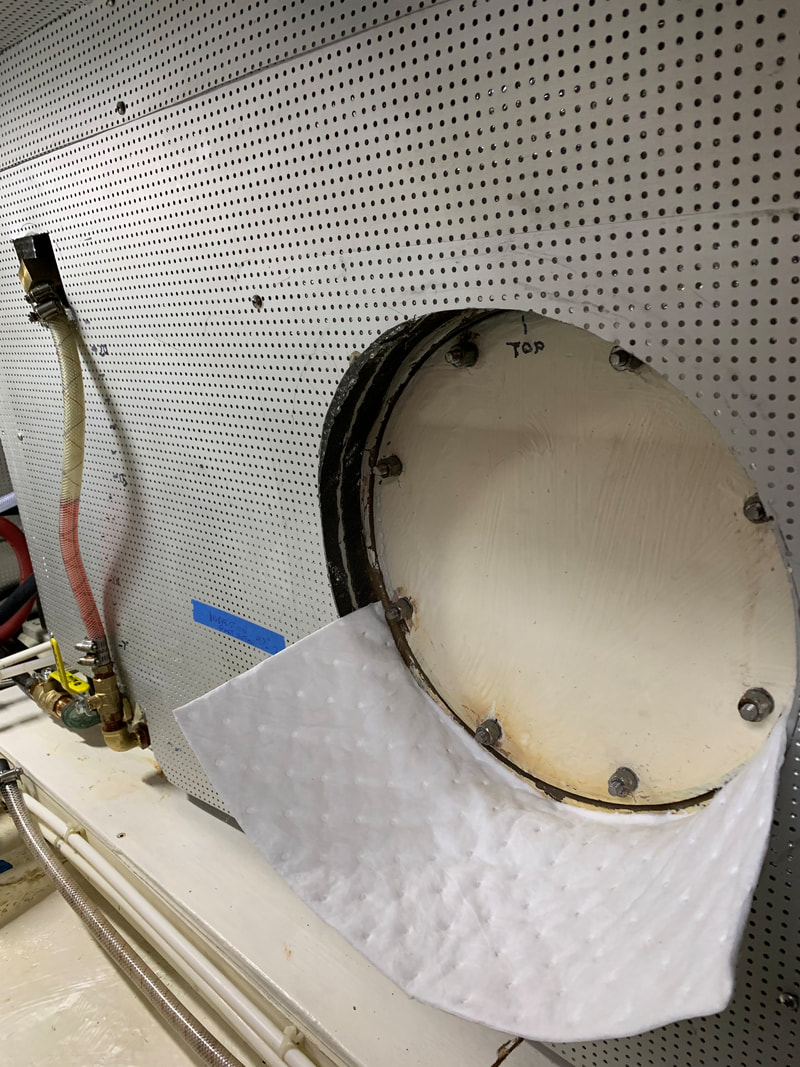

Now the agony and research. I had two different recommendations for a relatively complex and, in this case, difficult to apply two-part poly-sulfide sealant. It was difficult to apply because I couldn't reach and see the hole inside the tank for preparation and application of the sealant. Versus a recommendation I had from a mechanic I trust who said that a rubber gasket would work . This seemed too simple and straightforward and made me suspicious. I checked with one of the rocket scientists at our yacht club and found that neoprene rubber and diesel fuel are NOT a good choice, but that nitrile rubber is. So I bought an 1/8" sheet of this from, where else, Amazon and cut a round gasket for the brass fitting as well as a new gasket for the 12" diameter access port in the side of the tank.

It appears that the original gasket for the access port was probably neoprene rubber. I suspect this because when I measured the distance between the bolts on the tank and the distance between the bolt holes in the original gasket, it was swollen about 1/2" in 5" or 10%.

I also did not cut out the center of the gasket as it appeared to me that this provided a potential second path for the fuel to leak. I've installed the gaskets and transferred fuel from the starboard tank back into the port tank and have about 8" of head on the access port gasket and 15" of head on the brass valve. So far no new leaks.

I guess I'm a little slow; it’s taken me about five weeks to fix a stupid little leak. But the work appears to be successful. AFTER I've been to the fuel dock and topped off the tanks and bounced around the strait of Georgia once or twice, WITHOUT leaks - I'll consider the issue over.

Happy cruising. May your tanks never leak. Dale Miller Silly Goose

2 Comments

4/23/2019 10:23:16 am

I love reading fix-it narratives like this. I learn the most interesting things, like "neoprene rubber and diesel fuel are NOT a good choice, but that nitrile rubber is."

Reply

It's interesting to know that the transfer pump would help with moving the fuel from one tank to another to fix the leak. I can imagine how it would definitely be better to look for a Suzuki marine repair professional for this kind of issue with my brother's boat. It would give him the assurance that the technique that will be used is the best one for the model and brand that he has.

Reply

Leave a Reply. |

About Us

Fidalgo Yacht Club is best known as a cruising club, whose members share a passion for boats, the Pacific Northwest inland waterways, and a sense of comradery. Safe boat handling is a priority. Summer will find us on the water from Anacortes to SE Alaska. Wintertime we gather together in our clubhouse to gather knowledge from dinner speakers and educational “bar chats”. We cruise and learn together and welcome new members whether a seasoned mariner or first-time boater. Categories

All

Archives

November 2019

|

RSS Feed

RSS Feed